Expanded sheet metal is a versatile product Utilized in numerous industries for various apps as a consequence of its power, durability, and adaptability. In this post, We are going to delve deep into the manufacturing strategy of expanded sheet metallic, Discovering the ways concerned as well as approaches employed to build this special material.

Introduction to Expanded Sheet Metal

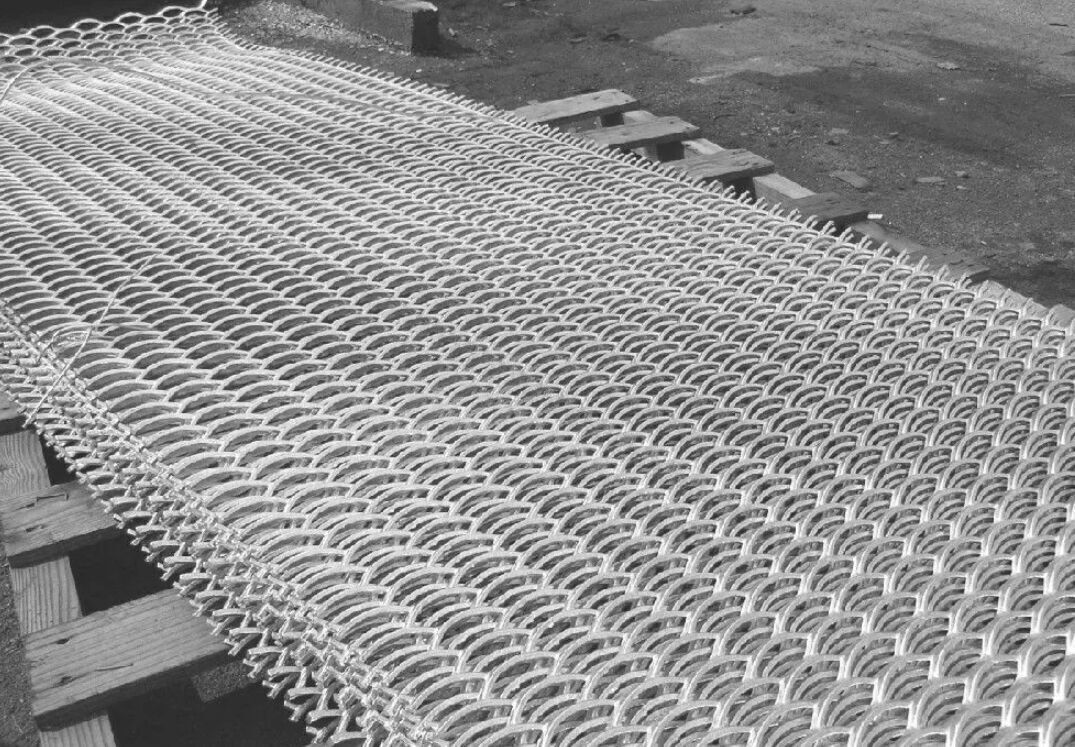

Expanded sheet steel is often a style of metal sheet which has been processed via a number of reducing and stretching operations to produce a pattern of diamond-formed openings. This method results in a material which is more robust plus more rigid than classic sheet metallic whilst still preserving a light-weight and flexible mother nature.

What is Expanded Sheet Metal?

Expanded sheet metallic is made by cutting slits within a steel sheet and afterwards stretching it to sort diamond-formed openings. This process enhances the surface area location of the material, which makes it stronger plus much more strong than typical sheet metal.

Why Select Expanded Sheet Steel?

Expanded sheet metallic features a number of rewards around conventional sheet metal, like increased toughness, rigidity, and flexibility. Additionally it is a lot more lightweight and price-effective, which makes it a perfect choice for a wide range of programs.

The Producing Process

The production process of expanded sheet steel involves several steps which might be very carefully executed to be sure the quality and regularity of the ultimate merchandise. Let us get a closer evaluate Just about every phase of the process:

1. Product Selection

The initial step within the production procedure is deciding upon the suitable content to the expanded sheet metal. Differing kinds of metals can be utilized, together with steel, aluminum, stainless-steel, and copper, depending upon the desired Houses of the ultimate product or service.

2. Cutting

Once the fabric has long been selected, it is cut into sheets of the specified dimension employing specialised reducing applications for example shears or laser cutters. The sheets are then cleaned and ready for the following phase of the method.

3. Slitting

In this phase, slits are made from the steel sheets employing a slitting equipment or press. The slits are strategically placed to create a unique sample that may be expanded later in the process.

4. Stretching

After the slitting approach is full, the metal sheets are fed into an growing machine that stretches them in equally Instructions to generate the diamond-shaped openings attribute of expanded sheet metal. The quantity of stretching used determines the size and form with the openings.

5. Flattening

Once the stretching approach is completed, the expanded sheets are flattened making use of rollers or presses to get rid of any wrinkles or imperfections brought about through expansion. This stage makes sure that the sheets are sleek and uniform in thickness.

6. Cutting to Size

The closing step during the manufacturing method entails chopping the expanded sheets to their ultimate dimensions using precision cutting instruments. This makes sure https://privatebin.net/?c487e62a06b83b54#5uoNEVCRpfZQgdvTHp42rdAnY5HpccqtzisneNWv9jiA that each sheet satisfies the necessary specs for its supposed application.

FAQs about Expanded Sheet Metal

Here are a few frequently questioned questions on expanded sheet metallic:

1. What exactly are some frequent programs of expanded sheet metal?

Expanded sheet steel is used in various industries for programs like fencing, grating, filters, screens, partitions, and ornamental uses.

2. Is expanded sheet metallic corrosion-resistant?

Yes, with regards to the kind of fabric employed (for instance chrome steel or aluminum), expanded sheet steel can be remarkably immune to corrosion, which makes it appropriate for outside use.

3. Can expanded sheet steel be painted or coated?

Yes, expanded sheet metallic might be painted or coated with protecting finishes to enhance its visual appearance and longevity although supplying more resistance to corrosion.

4. How does expanded sheet steel Look at to perforated sheet metallic?

Expanded sheet metal frequently has much larger openings than perforated sheet metal and features larger energy and rigidity resulting from its one of a kind manufacturing process.

5. What factors need to be considered when choosing expanded sheet metal for a certain application?

When picking expanded sheet metal for a selected software, factors for example product type, thickness, opening size, sample structure, complete, and environmental circumstances should be taken under consideration.